In several situations, and with the arrival of recent CNC slicing and bending equipment, sections is often manufactured in one ingredient, While Earlier welding or other becoming a member of tactics might be essential.

Spinning is really a sheet metal fabrication course of action unlike other deformation strategies in that it takes advantage of a lathe to rotate sheet metal as it can be pressed against a Instrument.

Bottom bending—commonly named “bottoming”—compresses the sheet metal to the bottom from the die to make the desired shape and angle. The form and posture from the die angle decide the final condition on the bend.

It’s a standard misconception that metal roofs usually tend to trigger damage and basic safety issues all through Severe temperature. Metal roofs don’t draw in lightning throughout a thunderstorm any in excess of conventional asphalt roofs.

Concealed fasteners are concealed underneath the metal panels applying clips or rails to get a cleaner, more seamless visual appearance.

All holes and cutouts are at the least 50% material thickness and adequately spaced away from the die line

The 6000 sequence is usually commonly Utilized in sheet metal bending. Workability exclusively makes it possible for the material for being bent to limited radii with out cracking, important for complex components (“Aluminium / Aluminium 1060 Alloy”).

Zinc material is crucial. Increased zinc degrees allow it to be considerably less malleable. Excellent for easy bends but sophisticated parts may require warmth.

The solutions detailed down below would not only tell you about the best way to bend sheet metal. They'd also show you which to use for the ideal outcome. The most typical sheet metal bending procedures are:

With a network of domestic and abroad fabricators, Xometry can source any amount of sheet metal pieces from small-quantity, superior-blend prototypes to significant-quantity creation runs. Xometry delivers competitive, customized sheet metal fabricating costs for reduced quantity prototypes and price discounts for prime volume manufacturing runs.

We’re about to go above some typical structure rules for bending, but be sure to take a look at our software program tutorials to check out distinct illustrations.

Bending sheet metals is Among the most frequent procedures in metal processing around the globe. When there are many variables that here must be dealt with when scheduling a sheet metal section layout, there are some common bending approaches that are essential to concentrate on to make sure your next sheet metal fabrication challenge makes its meant result.

The bend allowance describes the adjustment that’s created to account for the inclination of sheet metal to bend back again to its authentic kind. As sheet metal is bent from its original sort, its dimensions are altered. The pressure that’s placed on bend the sheet metal brings about it to extend and compress within and out of doors.

Sheet metal bending has become the necessary techniques inside the metal processing business. For instance, it is a crucial stage within the automotive companies considering the fact that they get the job done with diverse shapes to get the best car section that works with their style. The method may be at an industrial stage, in which it is perfect for producing big engine parts.

Alicia Silverstone Then & Now!

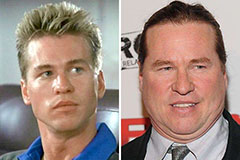

Alicia Silverstone Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now!